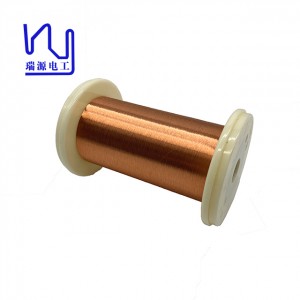

Intambo yethusi engu-0.05mm 2UEW/3UEW155/180 enamelisiwe yekhoyili yokukhanyisa

Umgomo osebenzayo wekhoyili yokushisa yemoto ukuguqula i-voltage ephansi yamandla e-DC ibe yi-voltage ephezulu ye-DC ngokuguqula kanye nokulungiswa kwe-voltage ephindwe kabili edlula ku-primary yekhoyili yokushisa ngezikhathi ezithile. I-voltage ephezulu ifakwa engxenyeni yesibili yekhoyili yokushisa (Ngokuvamile cishe i-20KV) bese iqhuba i-spark plug yekhoyili yokushisa ukuze ikhiphe ukuze ishise. Kunzima ukulawula ezinye izakhiwo zocingo olujwayelekile olune-enamel lwamakhoyili okushisa ezimoto njengoba ucingo oluphukile luvame ukwenzeka ngesikhathi senqubo. Uma sicabangela izidingo ezikhethekile zamakhoyili okushisa, inkampani yethu iklama ucingo olune-enamel oluhlukile lwamakhoyili okushisa ezimoto anokubukeka okuhle kakhulu, ukushiswa okuhle, ukumelana nokuthamba okuphezulu kanye nokuqina ngesikhathi sokukhiqiza. Sisebenzisa ucingo lwethusi oludonswe ngentambo oluqala lumbozwe nge-base coat soldering ekushiseni okuphansi. Bese ucingo lumbozwa nge-enamel engathambisi ukuthamba. Izingxenye zalolu cingo ziyi-polyurethane enokumelana nokushisa okuphezulu.

Esinye sezici zentambo ene-enamel (G2 H0.03-0.10) yesibili yekhoyili yokushisa yemoto ukuthi ububanzi bayo buncane kakhulu. Encane kakhulu cishe ingxenye eyodwa kwezintathu zezinwele zomuntu. Ngaphezu kwalokho, njengoba kuyintambo ene-enamel ejiyile ye-polyurethane yekilasi lokushisa elingu-180C, inezidingo eziphakeme kakhulu enkambisweni yokukhiqiza. Inkampani yethu inolwazi oluningi kanye nobuchwepheshe obuvuthiwe nobuthuthukisiwe ekwakhiweni kwentambo ene-enamel yekhoyili yokushisa yemoto. Inqubo yokukhiqiza izinzile.

1. Ukuthuthukiswa kokumelana nokuthambisa ukuze kungaphuki ngesikhathi sokuthambisa ngaphansi kwesimo esingu-260℃*2min.

2. Ukusebenza kahle kokugoqa, ubuso bokugoqa bubushelelezi futhi buhlanzekile ngaphandle kwe-slag ye-solder ngaphansi kwesimo esingu-390℃ * 2S.

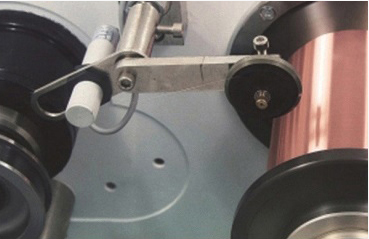

Izinga lokuphuka kwentambo enqubweni yokukhiqiza lincishisiwe lisuka ngaphezu kuka-20% liye ngaphansi kuka-1%, ukuze indawo ibushelelezi futhi ukuhanjiswa kwayo kuzinzile.

1. Samukela ukufakelwa okuhlanganisiwe: i-enamel enesimo sokugoqa esiphansi sokushisa isetshenziswa njengesisekelo, kanye ne-enamel enokumelana nokuthamba okuphezulu njenge-topcoat ukukhiqiza ucingo oluhlanganisiwe olune-enamel olunokuthamba okuhle kanye nokumelana nokuthamba okuphezulu.

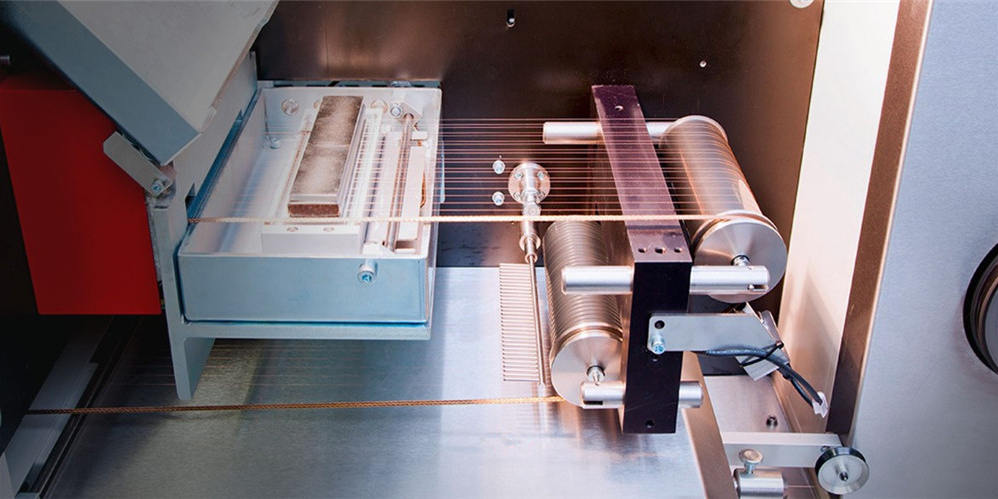

2. Ukuthuthukisa ubuchwepheshe bokukhiqiza ucingo olune-enamel: ukushintsha kokuhlushwa kukawoyela wokudonsa ngesikhathi sokudweba. Isethi yesikhunta yokuphathwa kokukhiqiza ivumela ubuso obubushelelezi bentambo yethusi. Ukufakwa kwedivayisi yokulungisa i-viscosity ezenzakalelayo kanye nedivayisi yokulawula ukucindezeleka okuzenzakalelayo enkambisweni yokuhlanganisa i-enamel kunciphisa izinga lokuphuka kwentambo.

| Ububanzi | Ukubekezelelana | Ucingo lwethusi olufakwe enamel (ububanzi obuphelele) | |||||

| (mm) | (mm) | Ibanga 1 | Ibanga lesi-2 | Ibanga lesi-3 | |||

| Ubuncane (mm) | Ubukhulu (mm) | Ubuncane (mm) | Ubukhulu (mm) | Ubuncane (mm) | Ubukhulu (mm) | ||

| 0.030 | * | 0.033 | 0.037 | 0.038 | 0.041 | 0.042 | 0.044 |

| 0.032 | * | 0.035 | 0.039 | 0.04 | 0.043 | 0.044 | 0.047 |

| 0.034 | * | 0.037 | 0.041 | 0.042 | 0.046 | 0.047 | 0.05 |

| 0.036 | * | 0.04 | 0.044 | 0.045 | 0.049 | 0.05 | 0.053 |

| 0.038 | * | 0.042 | 0.046 | 0.047 | 0.051 | 0.052 | 0.055 |

| 0.040 | * | 0.044 | 0.049 | 0.05 | 0.054 | 0.055 | 0.058 |

| 0.043 | * | 0.047 | 0.052 | 0.053 | 0.058 | 0.059 | 0.063 |

| 0.045 | * | 0.05 | 0.055 | 0.056 | 0.061 | 0.062 | 0.066 |

| 0.048 | * | 0.053 | 0.059 | 0.06 | 0.064 | 0.065 | 0.069 |

| 0.050 | * | 0.055 | 0.06 | 0.061 | 0.066 | 0.067 | 0.072 |

| 0.053 | * | 0.058 | 0.064 | 0.065 | 0.07 | 0.071 | 0.076 |

| 0.056 | * | 0.062 | 0.067 | 0.068 | 0.074 | 0.075 | 0.079 |

| 0.060 | * | 0.066 | 0.072 | 0.073 | 0.079 | 0.08 | 0.085 |

| 0.063 | * | 0.069 | 0.076 | 0.077 | 0.083 | 0.084 | 0.088 |

| 0.067 | * | 0.074 | 0.08 | 0.081 | 0.088 | 0.089 | 0.091 |

| 0.070 | * | 0.077 | 0.083 | 0.084 | 0.09 | 0.091 | 0.096 |

| 0.071 | ±0.003 | 0.078 | 0.084 | 0.085 | 0.091 | 0.092 | 0.096 |

| 0.075 | ±0.003 | 0.082 | 0.089 | 0.09 | 0.095 | 0.096 | 0.102 |

| 0.080 | ±0.003 | 0.087 | 0.094 | 0.095 | 0.101 | 0.102 | 0.108 |

| 0.085 | ±0.003 | 0.093 | 0.1 | 0.101 | 0.107 | 0.108 | 0.114 |

| 0.090 | ±0.003 | 0.098 | 0.105 | 0.106 | 0.113 | 0.114 | 0.12 |

| 0.095 | ±0.003 | 0.103 | 0.111 | 0.112 | 0.119 | 0.12 | 0.126 |

| 0.100 | ±0.003 | 0.108 | 0.117 | 0.118 | 0.125 | 0.126 | 0.132 |

| 0.106 | ±0.003 | 0.115 | 0.123 | 0.124 | 0.132 | 0.133 | 0.14 |

| 0.110 | ±0.003 | 0.119 | 0.128 | 0.129 | 0.137 | 0.138 | 0.145 |

| 0.112 | ±0.003 | 0.121 | 0.13 | 0.131 | 0.139 | 0.14 | 0.147 |

| 0.118 | ±0.003 | 0.128 | 0.136 | 0.137 | 0.145 | 0.146 | 0.154 |

| 0.120 | ±0.003 | 0.13 | 0.138 | 0.139 | 0.148 | 0.149 | 0.157 |

| 0.125 | ±0.003 | 0.135 | 0.144 | 0.145 | 0.154 | 0.155 | 0.163 |

| 0.130 | ±0.003 | 0.141 | 0.15 | 0.151 | 0.16 | 0.161 | 0.169 |

| 0.132 | ±0.003 | 0.143 | 0.152 | 0.153 | 0.162 | 0.163 | 0.171 |

| 0.140 | ±0.003 | 0.151 | 0.16 | 0.161 | 0.171 | 0.172 | 0.181 |

| 0.150 | ±0.003 | 0.162 | 0.171 | 0.172 | 0.182 | 0.183 | 0.193 |

| 0.160 | ±0.003 | 0.172 | 0.182 | 0.183 | 0.194 | 0.195 | 0.205 |

| 0.170 | ±0.003 | 0.183 | 0.194 | 0.195 | 0.205 | 0.206 | 0.217 |

| 0.180 | ±0.003 | 0.193 | 0.204 | 0.205 | 0.217 | 0.218 | 0.229 |

| 0.190 | ±0.003 | 0.204 | 0.216 | 0.217 | 0.228 | 0.229 | 0.24 |

| 0.200 | ±0.003 | 0.214 | 0.226 | 0.227 | 0.239 | 0.24 | 0.252 |

| Ububanzi | Ukubekezelelana | Ukumelana ku-20 °C | ||

| mm | mm | Igama(ohm/m) | Ubuncane(ohm/m) | Ubukhulu (ohm/m) |

| 0.030 | * | 24.18 | 21.76 | 26.6 |

| 0.032 | * | 21.25 | 19.13 | 23.38 |

| 0.034 | * | 18.83 | 17.13 | 20.52 |

| 0.036 | * | 16.79 | 15.28 | 18.31 |

| 0.038 | * | 15.07 | 13.72 | 16.43 |

| 0.040 | * | 13.6 | 12.38 | 14.83 |

| 0.043 | * | 11.77 | 10.71 | 12.83 |

| 0.045 | * | 10.75 | 9.781 | 11.72 |

| 0.048 | * | 9.447 | 8.596 | 10.3 |

| 0.050 | * | 8.706 | 7.922 | 9.489 |

| 0.053 | * | 7.748 | 7.051 | 8.446 |

| 0.056 | * | 6.94 | 6.316 | 7.565 |

| 0.060 | * | 6.046 | 5.502 | 6.59 |

| 0.063 | * | 5.484 | 4.99 | 5.977 |

| 0.067 | * | 4.848 | 4.412 | 5.285 |

| 0.070 | * | 4.442 | 4.042 | 4.842 |

| 0.071 | ±0.003 | 4.318 | 3.929 | 4.706 |

| 0.075 | ±0.003 | 3.869 | 3.547 | 4.235 |

| 0.080 | ±0.003 | 3.401 | 3.133 | 3.703 |

| 0.085 | ±0.003 | 3.012 | 2.787 | 3.265 |

| 0.090 | ±0.003 | 2.687 | 2.495 | 2.9 |

| 0.095 | ±0.003 | 2.412 | 2.247 | 2.594 |

| 0.100 | ±0.003 | 2.176 | 2.034 | 2.333 |

| 0.106 | ±0.003 | 1.937 | 1.816 | 2.069 |

| 0.110 | ±0.003 | 1.799 | 1.69 | 1.917 |

| 0.112 | ±0.003 | 1.735 | 1.632 | 1.848 |

| 0.118 | ±0.003 | 1.563 | 1.474 | 1.66 |

| 0.120 | ±0.003 | 1.511 | 1.426 | 1.604 |

| 0.125 | ±0.003 | 1.393 | 1.317 | 1.475 |

| 0.130 | ±0.003 | 1.288 | 1.22 | 1.361 |

| 0.132 | ±0.003 | 1.249 | 1.184 | 1.319 |

| 0.140 | ±0.003 | 1.11 | 1.055 | 1.17 |

| 0.150 | ±0.003 | 0.9673 | 0.9219 | 1.0159 |

| 0.160 | ±0.003 | 0.8502 | 0.8122 | 0.8906 |

| 0.170 | ±0.003 | 0.7531 | 0.7211 | 0.7871 |

| 0.180 | ±0.003 | 0.6718 | 0.6444 | 0.7007 |

| 0.190 | ±0.003 | 0.6029 | 0.5794 | 0.6278 |

| 0.200 | ±0.003 | 0.5441 | 0.5237 | 0.5657 |

I-Transformer

Injini

Ikhoyili yokushisa

Ikhoyili Yezwi

Izinto zikagesi

I-Relay

Kuqondiswe Kumakhasimende, Ukusungula Izinto Ezintsha Kuletha Inani Elikhulu

I-RUIYUAN ingumhlinzeki wezixazululo, okudinga ukuthi sibe ngochwepheshe kakhulu ezintanjeni, ezintweni zokuvikela kanye nezinhlelo zakho zokusebenza.

I-Ruiyuan inefa lokusungula izinto ezintsha, kanye nentuthuko ku-enamel copper wire, inkampani yethu ikhule ngokuzibophezela okungapheli ekuthembekeni, ekuhlinzekeni nasekuphenduleni amakhasimende ethu.

Silangazelela ukuqhubeka sikhula ngesisekelo sekhwalithi, ukusungula izinto ezintsha kanye nensizakalo.

Izinsuku eziyi-7-10 Isikhathi sokulethwa esimaphakathi.

Amakhasimende angama-90% aseYurophu naseNyakatho Melika. Njenge-PTR, i-ELSIT, i-STS njll.

Izinga lokuthenga kabusha elingu-95%

Izinga lokwaneliseka elingu-99.3%. Umhlinzeki weKlasi A uqinisekiswe yikhasimende laseJalimane.